This article presents an overview of the agent-based modeling and simulation approach and its recent developments in transport fields, with the purpose of discovering the advantages and gaps and encouraging more valuable investigations and applications of agent-based models. Moreover, the latest average departure time with no risk of being late when going to work is approximately 8:04, and the earliest average departure time with no risk of missing metro trips when getting off work is approximately 17:50. The results demonstrate that as the number of iterations increases, the average travel time of these person agents decreases by approximately 4 min. This study examines 103,637 person agents (passengers) in Shenzhen, China, and reports their average departure time, travel time and travel utility, as well as the numbers of person agents who are late and miss metro trips in every iteration. A strategy for identifying relatively optimal departure times is identified. This paper examines the optimal departure times of metro users during rush hour using a newly developed simulation tool. Such simulations focus on optimizing travel times by adjusting departure times, travel modes or travel routes to present travel suggestions to the public. It is also necessary to examine commuting-based traffic simulations. Activity-based traffic simulation models, such as MATSim (Multi-Agent Transport Simulation), are intended to identify optimal combinations of activities in time and space.

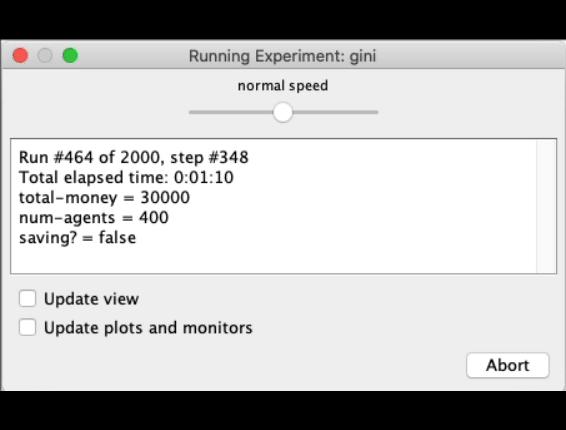

#Netlogo behavior space software#

Furthermore, the usability and the practicality of the proposed software tool facilitate its deployment and customization to different production chains, and provide a practical example of the use of multi‐agent systems and artificial intelligence in the context of industry 4.0.Īs serious traffic problems have increased throughout the world, various types of studies, especially traffic simulations, have been conducted to investigate this issue. The proposed agent‐based simulation model proved to be very efficient in promptly reacting to different dynamic scenarios and in suitably handling different situations. The overall system was tested in different scenarios, such as faults, changing operating conditions and off‐spec productions. The agents were modeled using the actor approach and the communication mechanism was based on the publish–subscribe paradigm. An event‐driven agent‐based simulation model composed of eight reactive agents was designed to simulate and control the operations of a generic industrial process.

In this paper, a smart industrial process based on intelligent software agents is presented with the aim of providing a technological solution to the specific needs of the process industry. Therefore, the use of technologies and methods that can transform traditional process industries into smart factories is necessary.

This will give you an idea of how variable the data is.Īn approach like this has been helpful for me in building an understanding of complex data.Process manufacturing industries are complex and dynamic systems composed of several processes, subject to many operations and unexpected events that can compromise overall system performance.

You can do that by reducing factors such as: the number of reporters you are recording, the number of runs per condition, the number of parameters you are varying, and the number of values you are using for each parameter. My thought is that you should first try generating and understanding a smaller set of data.

I wonder what your plan for analysis is if you are able to open the file in Excel or another tool. There have been a number of suggestions that may solve the problem of accessing your data.

0 kommentar(er)

0 kommentar(er)